What if Ultrasound Does Not Pick Up Baby's Heartbeat

Ultrasound paradigm (sonogram) of a fetus in the womb, viewed at 12 weeks of pregnancy (bidimensional scan)

An ultrasonic examination

Ultrasound is audio waves with frequencies higher than the upper audible limit of human hearing. Ultrasound is not dissimilar from "normal" (audible) sound in its physical properties, except that humans cannot hear it. This limit varies from person to person and is approximately 20 kilohertz (20,000 hertz) in healthy young adults. Ultrasound devices operate with frequencies from 20 kHz up to several gigahertz.

Ultrasound is used in many unlike fields. Ultrasonic devices are used to detect objects and measure distances. Ultrasound imaging or sonography is frequently used in medicine. In the nondestructive testing of products and structures, ultrasound is used to detect invisible flaws. Industrially, ultrasound is used for cleaning, mixing, and accelerating chemic processes. Animals such as bats and porpoises use ultrasound for locating prey and obstacles.[1]

History

Galton whistle, one of the beginning devices to produce ultrasound

Acoustics, the science of sound, starts as far dorsum as Pythagoras in the 6th century BC, who wrote on the mathematical properties of stringed instruments. Echolocation in bats was discovered by Lazzaro Spallanzani in 1794, when he demonstrated that bats hunted and navigated by inaudible audio, not vision. Francis Galton in 1893 invented the Galton whistle, an adjustable whistle that produced ultrasound, which he used to measure the hearing range of humans and other animals, demonstrating that many animals could hear sounds above the hearing range of humans. The commencement technological application of ultrasound was an attempt to observe submarines past Paul Langevin in 1917. The piezoelectric effect, discovered by Jacques and Pierre Curie in 1880, was useful in transducers to generate and observe ultrasonic waves in air and water.[two]

Definition

Gauge frequency ranges corresponding to ultrasound, with rough guide of some applications

Ultrasound is divers past the American National Standards Constitute as "sound at frequencies greater than xx kHz". In air at atmospheric pressure, ultrasonic waves take wavelengths of i.9 cm or less.

Perception

Humans

The upper frequency limit in humans (approximately 20 kHz) is due to limitations of the middle ear. Auditory sensation can occur if loftier‐intensity ultrasound is fed directly into the human skull and reaches the cochlea through bone conduction, without passing through the heart ear.[3]

Children tin hear some loftier-pitched sounds that older adults cannot hear, because in humans the upper limit pitch of hearing tends to decrease with age.[4] An American cell phone visitor has used this to create band signals that supposedly are only audible to younger humans,[5] but many older people can hear the signals, which may be because of the considerable variation of historic period-related deterioration in the upper hearing threshold. The Musquito is an electronic device that uses a loftier pitched frequency to deter loitering by immature people.

Animals

Bats utilize ultrasounds to navigate in the darkness.

A canis familiaris whistle, a whistle which emits audio in the ultrasonic range, used to train dogs and other animals

Bats utilise a variety of ultrasonic ranging (echolocation) techniques to find their prey. They can find frequencies beyond 100 kHz, possibly up to 200 kHz.[half dozen]

Many insects have good ultrasonic hearing, and most of these are nocturnal insects listening for echolocating bats. These include many groups of moths, beetles, praying mantids and lacewings. Upon hearing a bat, some insects will brand evasive manoeuvres to escape being caught.[seven] Ultrasonic frequencies trigger a reflex action in the noctuid moth that causes it to drop slightly in its flying to evade attack.[eight] Tiger moths also emit clicks which may disturb bats' echolocation,[ix] [x] and in other cases may advertise the fact that they are poisonous past emitting sound.[11] [12]

Dogs and cats' hearing range extends into the ultrasound; the top end of a canis familiaris's hearing range is nigh 45 kHz, while a cat'due south is 64 kHz.[xiii] [14] The wild ancestors of cats and dogs evolved this college hearing range to hear loftier-frequency sounds made by their preferred casualty, small rodents.[13] A canis familiaris whistle is a whistle that emits ultrasound, used for training and calling dogs. The frequency of about dog whistles is within the range of 23 to 54 kHz.[15]

Toothed whales, including dolphins, can hear ultrasound and apply such sounds in their navigational organisation (biosonar) to orient and to capture prey.[16] Porpoises have the highest known upper hearing limit at around 160 kHz.[17] Several types of fish can discover ultrasound. In the order Clupeiformes, members of the subfamily Alosinae (shad) have been shown to exist able to detect sounds up to 180 kHz, while the other subfamilies (e.thou. herrings) can hear only up to 4 kHz.[18]

Ultrasound generator/speaker systems are sold as electronic pest control devices, which are claimed to frighten abroad rodents and insects, only there is no scientific evidence that the devices work.[19] [20] [21]

Detection and ranging

Non-contact sensor

An ultrasonic level or sensing system requires no contact with the target. For many processes in the medical, pharmaceutical, armed services and full general industries this is an reward over inline sensors that may contaminate the liquids inside a vessel or tube or that may be chock-full by the product.

Both continuous wave and pulsed systems are used. The principle backside a pulsed-ultrasonic technology is that the transmit bespeak consists of short bursts of ultrasonic energy. After each burst, the electronics looks for a render point within a small window of fourth dimension corresponding to the fourth dimension it takes for the energy to pass through the vessel. Merely a signal received during this window will qualify for additional signal processing.

A popular consumer application of ultrasonic ranging was the Polaroid SX-70 photographic camera, which included a lightweight transducer system to focus the camera automatically. Polaroid after licensed this ultrasound technology and it became the basis of a diversity of ultrasonic products.

Movement sensors and flow measurement

A mutual ultrasound application is an automatic door opener, where an ultrasonic sensor detects a person's approach and opens the door. Ultrasonic sensors are likewise used to detect intruders; the ultrasound can cover a wide expanse from a single point. The catamenia in pipes or open channels can be measured past ultrasonic flowmeters, which measure the average velocity of flowing liquid. In rheology, an acoustic rheometer relies on the principle of ultrasound. In fluid mechanics, fluid catamenia tin can exist measured using an ultrasonic menses meter.

Nondestructive testing

Principle of flaw detection with ultrasound. A void in the solid material reflects some energy back to the transducer, which is detected and displayed.

Ultrasonic testing is a blazon of nondestructive testing commonly used to notice flaws in materials and to measure the thickness of objects. Frequencies of two to ten MHz are common, but for special purposes other frequencies are used. Inspection may be transmission or automated and is an essential office of modern manufacturing processes. Almost metals can be inspected also every bit plastics and aerospace composites. Lower frequency ultrasound (50–500 kHz) tin can likewise exist used to inspect less dense materials such as forest, concrete and cement.

Ultrasound inspection of welded joints has been an culling to radiography for nondestructive testing since the 1960s. Ultrasonic inspection eliminates the use of ionizing radiations, with safety and price benefits. Ultrasound tin also provide additional information such every bit the depth of flaws in a welded joint. Ultrasonic inspection has progressed from manual methods to computerized systems that automate much of the procedure. An ultrasonic examination of a articulation can place the existence of flaws, measure their size, and identify their location. Non all welded materials are as amenable to ultrasonic inspection; some materials take a large grain size that produces a high level of background noise in measurements.[22]

Non-destructive testing of a swing shaft showing spline cracking

Ultrasonic thickness measurement is 1 technique used to monitor quality of welds.

Ultrasonic range finding

Principle of an active sonar

A common use of ultrasound is in underwater range finding; this employ is besides called Sonar. An ultrasonic pulse is generated in a particular direction. If there is an object in the path of this pulse, part or all of the pulse will be reflected back to the transmitter every bit an echo and tin can be detected through the receiver path. Past measuring the difference in time between the pulse being transmitted and the echo existence received, it is possible to determine the distance.

The measured travel time of Sonar pulses in water is strongly dependent on the temperature and the salinity of the h2o. Ultrasonic ranging is besides practical for measurement in air and for short distances. For example, manus-held ultrasonic measuring tools tin can rapidly measure the layout of rooms.

Although range finding underwater is performed at both sub-audible and audible frequencies for keen distances (1 to several kilometers), ultrasonic range finding is used when distances are shorter and the accuracy of the distance measurement is desired to exist effectively. Ultrasonic measurements may exist limited through barrier layers with large salinity, temperature or vortex differentials. Ranging in h2o varies from about hundreds to thousands of meters, but can be performed with centimeters to meters accuracy

Ultrasound Identification (USID)

Ultrasound Identification (USID) is a Real-Fourth dimension Locating System (RTLS) or Indoor Positioning System (IPS) applied science used to automatically track and identify the location of objects in real time using uncomplicated, cheap nodes (badges/tags) fastened to or embedded in objects and devices, which then transmit an ultrasound signal to communicate their location to microphone sensors.

Imaging

Sonogram of a fetus at xiv weeks (profile)

The potential for ultrasonic imaging of objects, with a 3 GHz sound wave producing resolution comparable to an optical paradigm, was recognized by Sokolov in 1939, simply techniques of the time produced relatively low-dissimilarity images with poor sensitivity.[23] Ultrasonic imaging uses frequencies of 2 megahertz and higher; the shorter wavelength allows resolution of small internal details in structures and tissues. The power density is by and large less than 1 watt per square centimetre to avert heating and cavitation effects in the object under examination.[24] High and ultra high ultrasound waves are used in acoustic microscopy, with frequencies up to 4 gigahertz. Ultrasonic imaging applications include industrial nondestructive testing, quality command and medical uses.[23]

Acoustic microscopy

Acoustic microscopy is the technique of using audio waves to visualize structures too small to be resolved by the human center. Frequencies upwardly to several gigahertz are used in acoustic microscopes. The reflection and diffraction of audio waves from microscopic structures can yield information not available with lite.

Man medicine

Medical ultrasound is an ultrasound-based diagnostic medical imaging technique used to visualize muscles, tendons, and many internal organs to capture their size, construction and whatsoever pathological lesions with real time tomographic images. Ultrasound has been used by radiologists and sonographers to image the human being body for at least 50 years and has become a widely used diagnostic tool. The technology is relatively cheap and portable, especially when compared with other techniques, such as magnetic resonance imaging (MRI) and computed tomography (CT). Ultrasound is also used to visualize fetuses during routine and emergency prenatal care. Such diagnostic applications used during pregnancy are referred to as obstetric sonography. As currently applied in the medical field, properly performed ultrasound poses no known risks to the patient.[25] Sonography does not use ionizing radiation, and the power levels used for imaging are too low to cause agin heating or pressure furnishings in tissue.[26] [27] Although the long-term effects due to ultrasound exposure at diagnostic intensity are yet unknown,[28] currently near doctors experience that the benefits to patients outweigh the risks.[29] The ALARA (As Low As Reasonably Achievable) principle has been advocated for an ultrasound test – that is, keeping the scanning time and power settings as low as possible simply consistent with diagnostic imaging – and that by that principle nonmedical uses, which by definition are non necessary, are actively discouraged.[thirty]

Ultrasound is also increasingly being used in trauma and first assist cases, with emergency ultrasound becoming a staple of well-nigh EMT response teams. Furthermore, ultrasound is used in remote diagnosis cases where teleconsultation is required, such as scientific experiments in space or mobile sports team diagnosis.[31]

According to RadiologyInfo,[32] ultrasounds are useful in the detection of pelvic abnormalities and tin can involve techniques known equally abdominal (transabdominal) ultrasound, vaginal (transvaginal or endovaginal) ultrasound in women, and also rectal (transrectal) ultrasound in men.

Veterinary medicine

Diagnostic ultrasound is used externally in horses for evaluation of soft tissue and tendon injuries, and internally in particular for reproductive work – evaluation of the reproductive tract of the mare and pregnancy detection.[33] It may besides exist used in an external manner in stallions for evaluation of testicular condition and diameter as well equally internally for reproductive evaluation (deferent duct etc.).[34]

Past 2005, ultrasound applied science began to be used by the beef cattle manufacture to ameliorate animal health and the yield of cattle operations.[35] Ultrasound is used to evaluate fat thickness, rib centre area, and intramuscular fatty in living animals.[36] It is also used to evaluate the health and characteristics of unborn calves.

Ultrasound technology provides a means for cattle producers to obtain data that can be used to improve the breeding and husbandry of cattle. The technology can be expensive, and information technology requires a substantial time commitment for continuous data collection and operator preparation.[36] However, this technology has proven useful in managing and running a cattle breeding operation.[35]

Processing and power

High-ability applications of ultrasound often use frequencies between 20 kHz and a few hundred kHz. Intensities tin be very high; above 10 watts per square centimeter, cavitation can be inducted in liquid media, and some applications use up to thou watts per square centimeter. Such high intensities can induce chemic changes or produce significant furnishings past direct mechanical activeness, and tin can inactivate harmful microorganisms.[24]

Physical therapy

Ultrasound has been used since the 1940s by physical and occupational therapists for treating connective tissue: ligaments, tendons, and fascia (and too scar tissue).[37] Atmospheric condition for which ultrasound may be used for handling include the follow examples: ligament sprains, muscle strains, tendonitis, joint inflammation, plantar fasciitis, metatarsalgia, facet irritation, impingement syndrome, bursitis, rheumatoid arthritis, osteoarthritis, and scar tissue adhesion.

Biomedical applications

Ultrasound has diagnostic and therapeutic applications, which tin can be highly beneficial when used with dosage precautions.[38] Relatively high power ultrasound can intermission up stony deposits or tissue, accelerate the consequence of drugs in a targeted area, assist in the measurement of the elastic properties of tissue, and can exist used to sort cells or small particles for enquiry.

Ultrasonic impact handling

Ultrasonic impact treatment (UIT) uses ultrasound to enhance the mechanical and physical properties of metals.[39] It is a metallurgical processing technique in which ultrasonic energy is applied to a metal object. Ultrasonic treatment can result in controlled remainder compressive stress, grain refinement and grain size reduction. Low and loftier bicycle fatigue are enhanced and have been documented to provide increases up to ten times greater than not-UIT specimens. Additionally, UIT has proven effective in addressing stress corrosion cracking, corrosion fatigue and related issues.

When the UIT tool, made upwards of the ultrasonic transducer, pins and other components, comes into contact with the work piece it acoustically couples with the piece of work piece, creating harmonic resonance.[40] This harmonic resonance is performed at a carefully calibrated frequency, to which metals respond very favorably.

Depending on the desired effects of treatment a combination of different frequencies and displacement amplitude is applied. These frequencies range between 25 and 55 kHz,[41] with the deportation amplitude of the resonant body of between 22 and fifty µm (0.00087 and 0.0020 in).

UIT devices rely on magnetostrictive transducers.

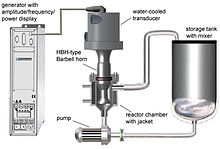

Processing

Ultrasonication offers great potential in the processing of liquids and slurries, past improving the mixing and chemic reactions in various applications and industries. Ultrasonication generates alternating low-pressure and high-pressure waves in liquids, leading to the formation and violent collapse of pocket-sized vacuum bubbles. This phenomenon is termed cavitation and causes high speed impinging liquid jets and strong hydrodynamic shear-forces. These effects are used for the deagglomeration and milling of micrometre and nanometre-size materials also as for the disintegration of cells or the mixing of reactants. In this aspect, ultrasonication is an alternative to high-speed mixers and agitator dewdrop mills. Ultrasonic foils under the moving wire in a paper motorcar will employ the shock waves from the imploding bubbles to distribute the cellulose fibres more uniformly in the produced paper web, which volition make a stronger paper with more even surfaces. Furthermore, chemical reactions benefit from the free radicals created by the cavitation also as from the free energy input and the textile transfer through boundary layers. For many processes, this sonochemical (see sonochemistry) effect leads to a substantial reduction in the reaction fourth dimension, similar in the transesterification of oil into biodiesel.[ citation needed ]

Schematic of bench and industrial-scale ultrasonic liquid processors

Substantial ultrasonic intensity and loftier ultrasonic vibration amplitudes are required for many processing applications, such every bit nano-crystallization, nano-emulsification,[42] deagglomeration, extraction, cell disruption, equally well as many others. Commonly, a procedure is first tested on a laboratory scale to evidence feasibility and establish some of the required ultrasonic exposure parameters. Subsequently this stage is complete, the process is transferred to a pilot (bench) scale for flow-through pre-production optimization and then to an industrial calibration for continuous production. During these calibration-up steps, information technology is essential to make sure that all local exposure conditions (ultrasonic amplitude, cavitation intensity, time spent in the active cavitation zone, etc.) stay the aforementioned. If this condition is met, the quality of the final product remains at the optimized level, while the productivity is increased by a predictable "scale-upward factor". The productivity increase results from the fact that laboratory, demote and industrial-scale ultrasonic processor systems contain progressively larger ultrasonic horns, able to generate progressively larger high-intensity cavitation zones and, therefore, to process more fabric per unit of time. This is called "direct scalability". Information technology is important to point out that increasing the power of the ultrasonic processor alone does not result in straight scalability, since information technology may exist (and oft is) accompanied past a reduction in the ultrasonic aamplitude and cavitation intensity. During directly calibration-up, all processing weather condition must be maintained, while the power rating of the equipment is increased in order to enable the operation of a larger ultrasonic horn.[43] [44] [45]

Ultrasonic manipulation and label of particles

A researcher at the Industrial Materials Research Institute, Alessandro Malutta, devised an experiment that demonstrated the trapping action of ultrasonic standing waves on wood pulp fibers diluted in water and their parallel orienting into the equidistant pressure level planes.[46] The time to orient the fibers in equidistant planes is measured with a laser and an electro-optical sensor. This could provide the paper industry a quick on-line cobweb size measurement arrangement. A somewhat different implementation was demonstrated at Pennsylvania State University using a microchip which generated a pair of perpendicular standing surface acoustic waves allowing to position particles equidistant to each other on a grid. This experiment, called acoustic tweezers, can be used for applications in material sciences, biology, physics, chemistry and nanotechnology.

Ultrasonic cleaning

Ultrasonic cleaners, sometimes mistakenly chosen supersonic cleaners, are used at frequencies from 20 to forty kHz for jewellery, lenses and other optical parts, watches, dental instruments, surgical instruments, diving regulators and industrial parts. An ultrasonic cleaner works mostly by energy released from the collapse of millions of microscopic cavitations near the dirty surface. The bubbling made by cavitation plummet forming tiny jets directed at the surface.

Ultrasonic disintegration

Similar to ultrasonic cleaning, biological cells including bacteria can be disintegrated. High power ultrasound produces cavitation that facilitates particle disintegration or reactions. This has uses in biological science for analytical or chemic purposes (sonication and sonoporation) and in killing bacteria in sewage. High power ultrasound can disintegrate corn slurry and enhance liquefaction and saccharification for higher ethanol yield in dry corn milling plants.[47] [48]

Ultrasonic humidifier

The ultrasonic humidifier, one blazon of nebulizer (a device that creates a very fine spray), is a popular type of humidifier. It works by vibrating a metallic plate at ultrasonic frequencies to nebulize (sometimes incorrectly called "disintegrate") the water. Considering the water is not heated for evaporation, it produces a cool mist. The ultrasonic pressure waves nebulize non just the water but also materials in the h2o including calcium, other minerals, viruses, fungi, bacteria,[49] and other impurities. Illness caused by impurities that reside in a humidifier'due south reservoir fall nether the heading of "Humidifier Fever".

Ultrasonic humidifiers are frequently used in aeroponics, where they are more often than not referred to as foggers.

Ultrasonic welding

In ultrasonic welding of plastics, high frequency (fifteen kHz to 40 kHz) low amplitude vibration is used to create heat by style of friction betwixt the materials to exist joined. The interface of the two parts is peculiarly designed to concentrate the energy for maximum weld force.

Sonochemistry

Power ultrasound in the twenty–100 kHz range is used in chemistry. The ultrasound does not interact straight with molecules to induce the chemical change, every bit its typical wavelength (in the millimeter range) is likewise long compared to the molecules. Instead, the energy causes cavitation which generates extremes of temperature and force per unit area in the liquid where the reaction happens. Ultrasound also breaks up solids and removes passivating layers of inert material to give a larger surface surface area for the reaction to occur over. Both of these effects brand the reaction faster. In 2008, Atul Kumar reported synthesis of Hantzsch esters and polyhydroquinoline derivatives via multi-component reaction protocol in aqueous micelles using ultrasound.[50]

Ultrasound is used in extraction, using different frequencies.

Wireless advice

In July 2015, The Economist reported that researchers at the Academy of California, Berkeley accept conducted ultrasound studies using graphene diaphragms. The thinness and depression weight of graphene combined with its force brand it an effective textile to use in ultrasound communications. One suggested application of the engineering would be underwater communications, where radio waves typically do not travel well.[51]

Ultrasonic signals have been used in "audio beacons" for cross-device tracking of Internet users.[52] [53]

Other uses

Ultrasound when applied in specific configurations can produce short bursts of lite in an exotic phenomenon known equally sonoluminescence. This phenomenon is beingness investigated partly because of the possibility of chimera fusion (a nuclear fusion reaction hypothesized to occur during sonoluminescence).

Ultrasound is used when characterizing particulates through the technique of ultrasound attenuation spectroscopy or past observing electroacoustic phenomena or by transcranial pulsed ultrasound.

Audio can be propagated past modulated ultrasound.

A formerly pop consumer application of ultrasound was in television set remote controls for adjusting volume and changing channels. Introduced by Zenith in the tardily 1950s, the organization used a mitt-held remote control containing short rod resonators struck by minor hammers, and a microphone on the set. Filters and detectors discriminated between the various operations. The principal advantages were that no battery was needed in the hand-held command box and, unlike radio waves, the ultrasound was unlikely to affect neighboring sets. Ultrasound remained in use until displaced past infrared systems starting in the belatedly 1980s.[54]

Safety

Occupational exposure to ultrasound in excess of 120 dB may lead to hearing loss. Exposure in excess of 155 dB may produce heating effects that are harmful to the human body, and information technology has been calculated that exposures above 180 dB may lead to death.[55] The U.k.'s independent Advisory Grouping on Not-ionising Radiation (AGNIR) produced a report in 2010, which was published by the Britain Health Protection Bureau (HPA). This report recommended an exposure limit for the general public to airborne ultrasound sound pressure levels (SPL) of lxx dB (at 20 kHz), and 100 dB (at 25 kHz and to a higher place).[56]

See also

- Acoustic droplet ejection

- Audio-visual emission

- Bat detector

- Delay-line memory

- Infrasound — sound at extremely low frequencies

- Isochoic

- Laser ultrasonics

- Phased array ultrasonics

- Picosecond ultrasonics

- Sonomicrometry

- Sound from ultrasound (also known equally hypersonic sound)

- Surface acoustic wave

- Ultrasonic motor

- Ultrasonic attenuation

- Ultrasound attenuation spectroscopy

References

- ^ Novelline R (1997). Squire'due south Fundamentals of Radiology (5th ed.). Harvard University Press. pp. 34–35. ISBN978-0-674-83339-5.

- ^ Pollet B (2012). "Chapter one". Ability Ultrasound in Electrochemistry: From Versatile Laboratory Tool to Technology Solution. John Wiley & Sons. ISBN978-1-119-96786-6.

- ^ Corso JF (1963). "Bone-conduction thresholds for sonic and ultrasonic frequencies". Journal of the Acoustical Society of America. 35 (11): 1738–1743. Bibcode:1963ASAJ...35.1738C. doi:10.1121/i.1918804.

- ^ Takeda S, Morioka I, Miyashita K, Okumura A, Yoshida Y, Matsumoto 1000 (1992). "Historic period variation in the upper limit of hearing". European Journal of Applied Physiology and Occupational Physiology. 65 (5): 403–viii. doi:ten.1007/BF00243505. PMID 1425644. S2CID 33698151.

- ^ Vitello P (12 June 2006). "A Ring Tone Meant to Fall on Deaf Ears". The New York Times.

- ^ Popper A, Fay RR, eds. (1995). Hearing past Bats. Springer Handbook of Auditory Research. Vol. v. Springer. ISBN978-ane-4612-2556-0.

- ^ Surlykke A, Miller LA (2001). "How some insects detect and avoid existence eaten by bats: Tactics and counter tactics of prey and predator". BioScience. 51 (7): 570. doi:ten.1641/0006-3568(2001)051[0570:HSIDAA]ii.0.CO;ii.

- ^ Jones Thousand, Waters DA (August 2000). "Moth hearing in response to bat echolocation calls manipulated independently in time and frequency". Proceedings. Biological Sciences. 267 (1453): 1627–32. doi:x.1098/rspb.2000.1188. PMC1690724. PMID 11467425.

- ^ Kaplan M (July 17, 2009). "Moths Jam Bat Sonar, Throw the Predators Off Course". National Geographic News. Archived from the original on 2009-08-22. Retrieved 2009-08-26 .

- ^ "Some Moths Escape Bats By Jamming Sonar". Talk of the Nation. National Public Radio. Archived from the original on 2017-08-10.

- ^ Surlykke A, Miller LA (1985). "The influence of arctiid moth clicks on bat echolocation; jamming or alarm?" (PDF). Journal of Comparative Physiology A. 156 (6): 831–843. doi:10.1007/BF00610835. S2CID 25308785. Archived from the original (PDF) on 2012-04-25.

- ^ Tougaard J, Miller LA, Simmons JA (2003). "The role of arctiid moth clicks in defense against echolocating bats: interference with temporal processing". In Thomas J, Moss CF, Vater M (eds.). Advances in the report of echolocation in bats and dolphins. Chicago: Chicago University Press. pp. 365–372.

- ^ a b Krantz L (2009). Power of the Canis familiaris: Things Your Dog Tin Do That You Tin't. MacMillan. pp. 35–37. ISBN978-0312567224.

- ^ Strain GM (2010). "How Well Do Dogs and Other Animals Hear?". Prof. Strain'due south website. School of Veterinary Medicine, Louisiana State Academy. Archived from the original on August viii, 2011. Retrieved July 21, 2012.

- ^ Coile DC, Bonham MH (2008). "Why Do Dogs Like Balls?: More Than 200 Canine Quirks, Curiosities, and Conundrums Revealed". Sterling Publishing Visitor, Inc: 116. ISBN978-1-4027-5039-7.

- ^ Whitlow WL (1993). The sonar of dolphins. Springer. ISBN978-0-387-97835-2 . Retrieved xiii Nov 2011.

- ^ Kastelein RA, Bunskoek P, Hagedoorn M, Au WW, de Haan D (July 2002). "Audiogram of a harbor porpoise (Phocoena phocoena) measured with narrow-band frequency-modulated signals". The Journal of the Acoustical Society of America. 112 (i): 334–44. Bibcode:2002ASAJ..112..334K. doi:10.1121/1.1480835. PMID 12141360.

- ^ Mann DA, Higgs DM, Tavolga WN, Souza MJ, Popper AN (June 2001). "Ultrasound detection by clupeiform fishes". The Periodical of the Acoustical Lodge of America. 109 (6): 3048–54. Bibcode:2001ASAJ..109.3048M. doi:ten.1121/1.1368406. PMID 11425147.

- ^ Hui YH (2003). Nutrient institute sanitation. CRC Printing. p. 289. ISBN978-0-8247-0793-four.

- ^ Vertebrate pests: issues and control; Volume 5 of Principles of constitute and creature pest control, National Research Council (U.S.). Committee on Plant and Beast Pests; Issue 1697 of Publication (National Research Council (U.S.))). National Academies. 1970. p. 92.

- ^ Jackson WB, McCartney WC, Ashton Advertisement (1989). "Protocol for Field Tests of Ultrasonic Devices for Rodent Management". In Fagerstone KA, Curnow RD (eds.). Vertebrate pest control and management materials. Vol. 6. ASTM International. p. viii. ISBN978-0-8031-1281-0.

- ^ Buschow KH, et al., eds. (2001). Encyclopedia of Materials. Elsevier. p. 5990. ISBN978-0-08-043152-9.

- ^ a b Papadakis EP, ed. (1999). Ultrasonic Instruments & Devices. Academic Press. p. 752. ISBN978-0-12-531951-5.

- ^ a b Betts GD, Williams A, Oakley RM (2000). "Inactivation of Food-borne Microorganisms using Power Ultrasound". In Robinson RK, Batt CA, Patel PD (eds.). Encyclopedia of Food Microbiology. Academic Press. p. 2202. ISBN978-0-12-227070-three.

- ^ Hangiandreou NJ (2003). "AAPM/RSNA physics tutorial for residents. Topics in Us: B-mode United states of america: bones concepts and new technology". Radiographics. 23 (4): 1019–33. doi:10.1148/rg.234035034. PMID 12853678.

- ^ Center for Devices and Radiological Health. "Medical Imaging – Ultrasound Imaging". www.fda.gov . Retrieved 2019-04-18 .

- ^ Ter Haar G (August 2011). "Ultrasonic imaging: prophylactic considerations". Interface Focus. 1 (four): 686–97. doi:10.1098/rsfs.2011.0029. PMC3262273. PMID 22866238.

- ^ "FDA Radiological Wellness – Ultrasound Imaging". United States Food and Drug Administration. 2011-09-06. Archived from the original on 2015-07-03. Retrieved 2011-eleven-thirteen .

- ^ "Patient Information – Ultrasound Safe". American Institute of Ultrasound in Medicine. Archived from the original on 2007-02-21.

- ^ "American Constitute for Ultrasound in Medicine do guidelines". American Establish for Ultrasound in Medicine. Archived from the original on 2015-07-01. Retrieved 2015-07-01 .

- ^ "DistanceDoc and MedRecorder: New Approach to Remote Ultrasound Imaging Solutions". Epiphan Systems. Archived from the original on 2011-02-fourteen.

- ^ "Ultrasound Imaging of the Pelvis". radiologyinfo.org. Archived from the original on 2008-06-25. Retrieved 2008-06-21 .

- ^ Pycock JF. "Ultrasound characteristics of the uterus in the cycling mare and their correlation with steroid hormones and timing of ovulation". Archived from the original on 31 January 2009.

- ^ McKinnon AO, Voss JL (1993). Equine Reproduction. Lea & Febiger. ISBN978-0-8121-1427-0.

- ^ a b Bennett D (May 19, 2005). "Subiaco Abbey'southward Angus herd". Delta Farm Press. Archived from the original on April 4, 2007. Retrieved February 27, 2010.

- ^ a b Wagner West. "Extension Effort in Beefiness Cattle Convenance & Option". West Virginia University Extension Service. Archived from the original on December 14, 2008. Retrieved Feb 27, 2010.

- ^ Watson T (2006). "Therapeutic Ultrasound" (PDF). Archived from the original (PDF) on 2007-04-12. for a pdf version with the author and appointment information)

- ^ Rapacholi MH, ed. (1982). Essentials of Medical Ultrasound: A Practical Introduction to the Principles, Techniques and Biomedical Applications. Humana Press.

- ^ Statnikov E. "Physics and mechanism of ultrasonic touch on handling". International Institute of Welding.

- ^ "UIT Solutions Video". appliedultrasonics.com. Archived from the original on 2012-05-ten. Retrieved 28 September 2012.

- ^ "Tools of the Merchandise". appliedultrasonics.com. Archived from the original on 2008-05-31. Retrieved 28 September 2012.

- ^ Peshkovsky AS, Peshkovsky SL, Bystryak S (July 2013). "Scalable high-power ultrasonic technology for the production of translucent nanoemulsions". Chemic Engineering and Processing: Process Intensification. 69: 77–82. doi:10.1016/j.cep.2013.02.010.

- ^ Peshkovsky SL, Peshkovsky AS (March 2007). "Matching a transducer to water at cavitation: acoustic horn design principles". Ultrasonics Sonochemistry. 14 (3): 314–22. doi:ten.1016/j.ultsonch.2006.07.003. PMID 16905351.

- ^ Peshkovsky Every bit, Peshkovsky SL (2010). "Industrial-calibration processing of liquids by loftier-intensity acoustic cavitation-the underlying theory and ultrasonic equipment design principles". In Nowak FM (ed.). Sonochemistry: Theory, Reactions and Syntheses, and Applications. Hauppauge, NY: Nova Science Publishers.

- ^ Peshkovsky AS, Peshkovsky SL (2010). Audio-visual cavitation theory and equipment design principles for industrial applications of high-intensity ultrasound. Physics Research and Technology. Hauppauge, NY: Nova Science Publishers.

- ^ Dion JL, Malutta A, Cielo P (November 1982). "Ultrasonic inspection of fiber suspensions". Periodical of the Acoustical Club of America. 72 (five): 1524–1526. Bibcode:1982ASAJ...72.1524D. doi:10.1121/one.388688.

- ^ Akin B, Khanal SK, Sung S, Grewell D (2006). "Ultrasound pre-treatment of waste activated sludge". H2o Science and Technology: Water Supply. vi (6): 35. doi:10.2166/ws.2006.962.

- ^ Neis U, Nickel K, Tiehm A (November 2000). "Enhancement of anaerobic sludge digestion by ultrasonic disintegration". Water Scientific discipline and Applied science. 42 (9): 73. doi:10.2166/wst.2000.0174.

- ^ Oie Due south, Masumoto North, Hironaga Thou, Koshiro A, Kamiya A (1992). "Microbial contagion of ambience air by ultrasonic humidifier and preventive measures". Microbios. 72 (292–293): 161–6. PMID 1488018.

- ^ Atul One thousand, Ram AM (2008). "Efficient Synthesis of Hantzsch Esters and Polyhydroquinoline Derivatives in Aqueous Micelles". Synlett. 2008 (6): 883–885. doi:10.1055/s-2008-1042908.

- ^ "Acoustic chatter". The Economist. economist.com. 2015-07-xi. Archived from the original on 2015-07-24. Retrieved 2015-07-23 .

- ^ Arp, Daniel. "Privacy Threats through Ultrasonic Side Channels on Mobile Devices". IEEE European Symposium on Security and Privacy: 1–13 – via IEEE Xplore.

- ^ Mavroudis, Vasilios (2017). "On the Privacy and Security of the Ultrasound Ecosystem". Proceedings on Privacy Enhancing Technologies. 2017 (2): 95–112. doi:x.1515/popets-2017-0018. S2CID 5068807 – via Sciendo.

- ^ Butler JG (2006). Television: Critical Methods and Applications. Routledge. p. 276. ISBN978-0-8058-5415-2.

- ^ Part II, industrial; commercial applications (1991). Guidelines for the Condom Employ of Ultrasound Office 2 – Industrial & Commercial Applications – Condom Code 24. Health Canada. ISBN978-0-660-13741-4. Archived from the original on 2013-01-10.

- ^ AGNIR (2010). Health Effects of Exposure to Ultrasound and Infrasound. Health Protection Agency, UK. pp. 167–170. Archived from the original on 2011-11-08. Retrieved 2011-xi-16 .

Further reading

- Kundu T (2004). Ultrasonic nondestructive evaluation: technology and biological textile characterization. Boca Raton, FL: CRC Press. ISBN978-0-8493-1462-9.

- Grzesik J, Pluta East (1983). "High-frequency hearing adventure of operators of industrial ultrasonic devices". International Archives of Occupational and Environmental Health. 53 (ane): 77–88. doi:ten.1007/BF00406179. PMID 6654504. S2CID 37176293.

External links

- Guidelines for the Condom Use of Ultrasound: valuable insight on the boundary conditions tending towards abuse of ultrasound

Source: https://en.wikipedia.org/wiki/Ultrasound

0 Response to "What if Ultrasound Does Not Pick Up Baby's Heartbeat"

Post a Comment